Small batch production plastic molding machine

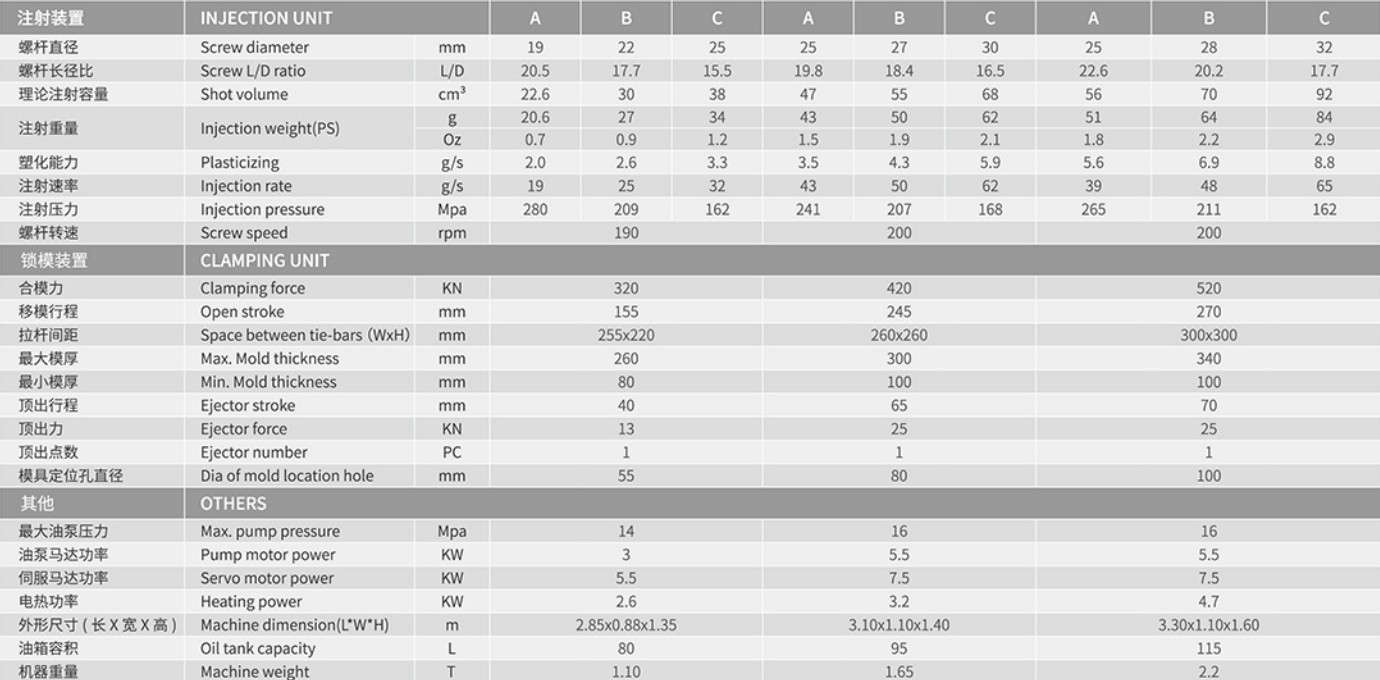

0.7-2.9 Oz/20-80 grams per shot, 22.6-92 CM3 shot volume

Features of the Servo Injection Molding Machine

Double cylinder balanced injection system;

Multi-stage pressure &speed injection;

Back pressure adjustment device;

Low-pressure mold protection;

Single hydraulic core pulling and inserting;

Multiple hydraulic ejector knock-out;

Mechanical, electrical safety device;

Auto lubrication system;

Hydraulic pressure full proportional control;

Computer control system;

Molding data memory system;

Automatic mold adjust function;

Energy-saving with servo motor;

For small Injection Molding Machine specifications please find the following link

https://drive.google.com/drive/folders/1GANHLaLKaKWKI6JfecFJyKh8lSN3HMac?usp=sharing

Techmation Q8 Controller is adopted for easy comprehension. A detailed user interface and a manual can be found below on Google Drive.

https://drive.google.com/file/d/1BAGuPdbsC-I8bTzmc4FgBlVrDIi5k5P5/view?usp=sharing

Servo Injection Molding Machine

What is a Servo Injection Molding Machine?

The traditional injection molding machine is using AC motors. In a Servo Injection Molding Machine servo motors are used in place of the normal AC motors. Servo motors can be used on all the drives of the machine, like pump motors and injection unit drives. Servo motors have many advantages over normal AC motors, higher reliability, energy-saving, etc.

Run a test before packing and shipping.

Chat Online

Chat Online