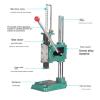

Pneumatic Embossing or Bronzing Machine

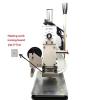

Standard maximum temperature: 399 degrees

Heating plate dimension: 100*130

Pneumatic press pressure 120Kgs or 200Kgs

Heating aluminum plate size can be customized

First, the working principle

This product uses compressed air as the power, the heating tube acts as a heat source, and the heating plate is installed under the cylinder.

It is fixed on the plane of the heating plate. Compressed air is connected to the cylinder through the air source processor and solenoid valve.

The magnetic valve is energized and de-energized to control the opening and closing of the gas path, thereby controlling the lifting and lowering of the cylinder, and the mold is baked on the workpiece.

The effect of printing.

Second, the main features:

1. The cylinder is used as the power actuator, and the movement is stable and reliable.

2. There is no impact during the work process, which can greatly improve work efficiency, processing quality and mold life.

3. Two-handed button operation, high security; (optional footswitch standby, release hands to improve work efficiency).

4. The hot stamping press time, output, and temperature can be adjusted.

5. The height of the hot stamping head can be adjusted and balanced.

6. Automatic counting function.

Third, technical parameters:

Working voltage: AC220V 50HZ;

Working pressure: 0.2-0.8MPA (2-8kg/cm3);

Working environment: -5 ° C ~ 50 ° C.

Power: 500-1000W

Temperature range: 0-399 degrees

Chat Online

Chat Online