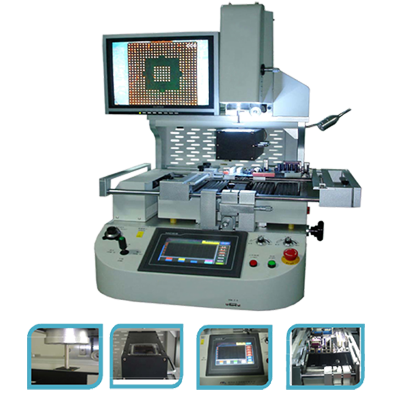

Infrared BGA Rework Station

Application: It's applied in repairing all kinds of BGA

chip sets from mobile, Set-Top Box, laptop, cell phone, desktop, computer, xbox360,sp3, receiver, game player, etc.

Specifications and technical parameters

Power: AC 220V±10% 50/60 Hz

Total Power: Max 5300W

Heater power: Top heater 1200 W Bottom heater 1200 W IR heater 2700 W

Electrical materials: intelligence Programmable controller, support connect computer

Temperature control: K-type thermocouple (Closed Loop), independence temperature control, accuracy within±3℃

Positioning: V-groove, PCB support

PCB size: Max 410×370 mm Min 65×65 mm

BGA chip: Max 80×80mm Min 2×2 mm

Dimensions: L640×W630×H900 mm

Sensors:1 pc

Color: white

FOB 10 days after deposit

Features

3 independent control heatersHot-air heating on the top and bottom heaters, the third IR heater is infrared heating, the top and bottom heaters can heat PCB from upper and bottom at the same time. temperature accuracy within ±3℃,there are multi segments that can be set at the same time; IR preheating area is adjustable according to requests, to make PCB heating evenly.

It can heat PCB board and BGA chips at the same time. And the third IR heater can preheat the PCB board from the bottom, to avoid PCB from deformation during the repair process. The top and bottom heaters heat independently; Choose high accurate K type close-loop thermocouple, and PID parameters automatic adjustment system, it can show seven temperature curves and the millions of groups data can be saved through U storage device,with instant curves analysis function and analyzing BGA temperature at any time; the sensor is for precise temperature testing.

The precise optical alignment system

Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions have automatic chromatism resolution and brightness adjustment system, amplify to 230 X, mounting accuracy within ±0.01mm.

Multi-function operation system

Adopt high definition human-machine interface, available for setting “set up” and “operate” to avoid error settings, The top heater device and mounting head 2 in 1 design, with automatic identify BGA chips and mounting height, it is of automatic soldering and desoldering function.it can set 6 segments rising

Temperature and 6 segments activity temperature, and can save N groups temperature profiles.

Adopted all kinds of BGA nozzles, with 360° rotation, easy for installation and replacement, customized is available;

V-groove PCB support, with rapid, convenient, and accurate positioning, can fit for all kinds of PCB board; Flexible and removable universal fixture has protective effects and no damage to the PCB board, suitable for all kinds of sizes of BGA repair.

Superior safety functions

With CE certification; after desoldering and soldering, there is alarming. when the temperature goes out of control the circuit will automatically power off, it is of double over-temperature protection function. Temperature parameter has a password to avoid arbitrary changes, with superior safety protection functions, can protect PCB board components and the machine from damage in an abnormal situation