Description: Automatically Vertical Type Powder Packaging Machine for small bags, sachets, pouches, pillow bags.

A vertical powder bag filling machine, also known as a vertical form-fill-seal (VFFS) machine, is a type of packaging equipment used to automatically fill and seal bags with powdered products. It is commonly used in industries such as food, pharmaceuticals, chemicals, and agricultural products. This VFFS powder packaging machine is designed for packing powder or granular products into small bags, sachets, pouches.

Main Features:

All the works of the forming bags, measuring weight, powders filling and bags sealing, cutting can be done automatically.

A coding printer is installed on the machine, can printing the date and batch number at the same time.

HMI operation, PLC control, drive stepper motor to control the bag length, easy to adjust accurate detection. Adopts intelligent temperature controller and PID control to ensure the error range of temperature controlled within 1 degree℃.

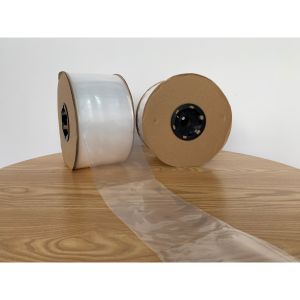

Package material: BOPP/Polyethylene, Aluminum/Polyethylene, Paper/Polyethylene, Polyester/Aluminizer/Polyethylene, Nylon/CPP and so on.

Sealing type: three sides sealing, four sides sealing, back sealing.

Technical parameters:

| Model | VF-61F |

| Measuring scope | 1-100g (3-100ml) |

| Bag size | L: 30-170mm, W: 30-130mm |

| Packing speed | 30-60bags/min |

| Total power | 110-220V, 50/60Hz, |

| Dimension | 900*1100*1900mm |

Main parts (optional parts) of VF-61F powder filling machine

Hopper: The machine is equipped with a large hopper that holds the powdered or granular material to be filled into the bags.

Auger or Screw Measuring: An auger or screw conveyor is used to transport the material from the hopper to the filling area. It ensures a controlled and precise flow of the powder or granules into the bags

Bag Forming System: The machine forms the bags from a roll of packaging material, such as heat-sealable plastic film or laminates. The bag forming system seals the bottom of the bag and creates a vertical tube to hold the product.

Filling System: The filling system consists of a vertical tube, which is clamped or held open at the top to receive the product. The auger or screw conveyor dispenses the precise amount of powder or granules into the bag.

Weighing or Measuring System: To ensure accurate filling, many vertical powder bag filling machines incorporate a weighing or measuring system. This system can be load cells or sensors that monitor the weight of the material being filled into the bag.

Sealing Mechanism: Once the bag is filled, it moves to a sealing station where the top of the bag is sealed. The sealing mechanism can use heat sealing, ultrasonic sealing, or other methods depending on the packaging material and requirements.

Bag Discharge Conveyor (optional): After sealing, the filled and sealed bags are discharged from the machine onto a conveyor belt or another packaging line for further processing or transportation.

Vertical powder bag filling machines are designed to handle a wide range of bag sizes and filling capacities. They offer high efficiency, accuracy, and automation, reducing manual labor and improving productivity in packaging operations.