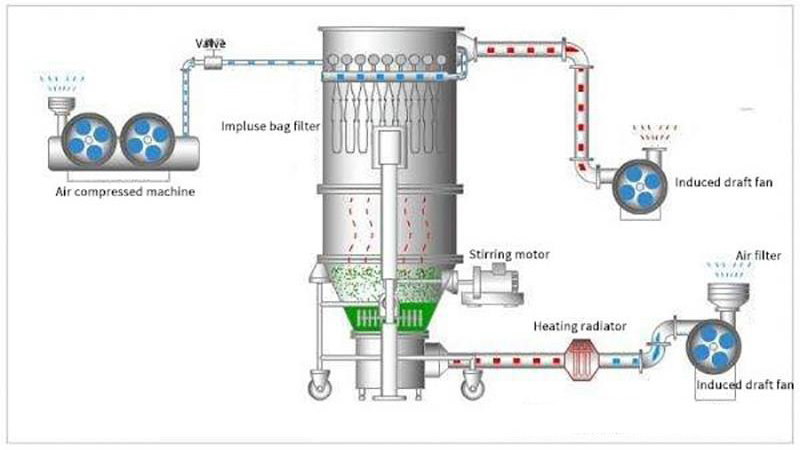

Fluidized Bed Dryer

A fluidized Bed Dryer is mainly used for medicine, food, chemical, and other industrial powder or dry granular materials. Fluid-bed Dryer is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, drying, etc, It is also widely used in such industries as medicine, chemical industry, food, etc.

Vertical Fluidized Bed Dryer

1 Fluidized drying, fast mass transfer

2 The negative pressure in the closed state of operation, no dust

3 Mining antistatic filter material, safe operation

4 The device has no dead ends, thorough cleaning, and no cross-contamination, according to the special needs, it can increase the stirring mechanism, and vacuum feeding system

5 Compared with the GFG, there is a greater flow of space.

The heated and purified air is introduced from the bottom-induced draft fan through the hole hopper screen. In the working chamber, negative pressure is formed by mixing and fluidization and the water is evaporated and removed, and the material is quickly and quickly dried

The fluidized bed is a round structure, to avoid dead ends

The hopper stirred to avoid agglomeration of raw material and forming a canal of flow when dry

Use Overturning discharge, to facilitate prompt and thorough

Seal negative pressure operation, the gas through the filter

Drying speed, temperature uniformity, each batch of drying time is generally 15-45 minutes.

Applications

Mechanism screw extrusion particles, rock particles, high-speed mixing wet granules.

Medicine, food, feed, chemical, and other fields of wet granules dried, and powdered materials.

Large particles, small block, sticky block granular materials.

Dry material volume change konjac, polyacrylamide.