Two-roll rubber mill for Rubber Compounding

3 inches lab use open mill

It's suitable for rubber and plastics polymer plasticized and scatted, the machine uses water cooling, electric heating, hot kerosene heating system. The roller can heat evenly, and cool quickly. It’s a dual-use machine, start heating system can be used to mix plastic, open the cooling system can be used to refine rubber.

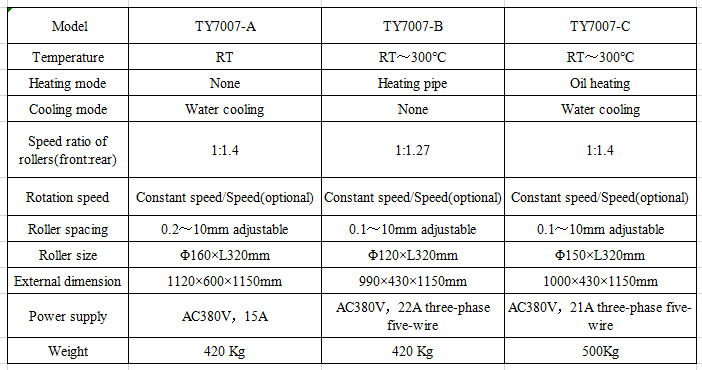

Technical parameter:

To create a rubber compound on a two-roll rubber mill, first, a raw polymer, or base polymer, is needed. The polymer can be several things, including natural rubber, such as SMR CV, SMR 20, SMR L, or a variety of synthetic rubbers such as nitrile(NBR), ethylene propylene diene monomer (EPDM), butyl, polychloroprene (CR), Polyisoprene (IR) and others.

Raw rubber after being masticated, which is normally for natural rubber, other ingredients need to be compounded into the raw polymer either on a mixing Banbury Kneader or other rubber mixing machines then passed to two roll mills for dispersion and sheeting out for rubber compound that is suitable for molding dimension. Rubbing compounding also can be mixed on two roll mills by sequentially adding the ingredients and folding, cutting, and rolling the rubber to mix. This process creates rubber that can be used to create products.

Ingredients added to make a rubber compound include oils, fillers, and accelerator, which usually includes sulfur or peroxide, and may also include a metal oxide either as an activator such as zinc oxide, in some cases as a filler, and also as an activator. After mixing, a compound is removed from the mill in a large sheet and then molded into its desired product.