Single extruder screw and barrel

CAD files for the 16mm and 20mm screw and barrel please check the link below

https://grabcad.com/library/robotdigg-16mm-and-20mm-screw-for-extrusion-1

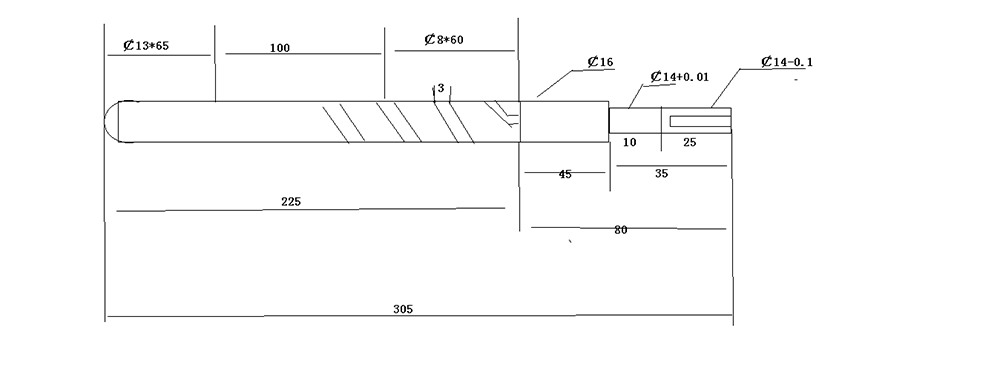

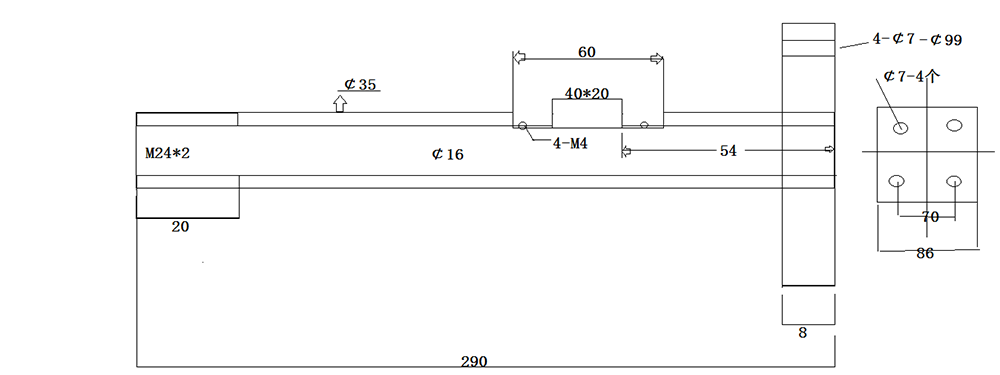

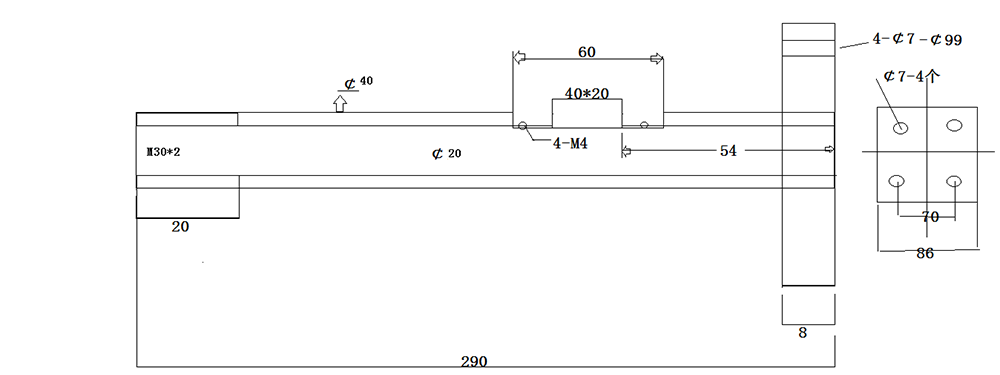

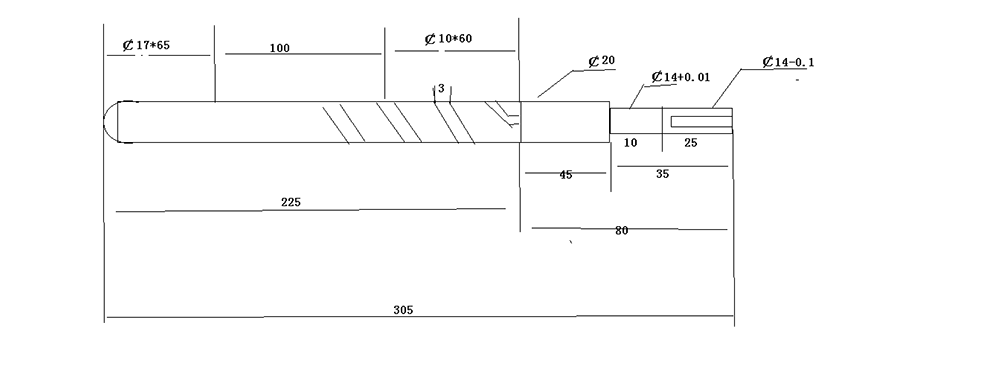

Small size 16mm or 20mm extruder screw and barrel for desktop plastic extruders

Technical Information

Main Base materials

1.38CrMoAlA (SACM645)

2.SKD-61 (Special Tool Steel)

3.42CrMo (Ultrahigh Strength Steel)

4.DC53 (Cold Work Die Steel)

5.W6Mo5Cr4V2 (High-Speed Tool Steel)

Main Alloy Materials

1. Ni-based alloy/Deloro alloy

2. Tungsten carbide/Wolfram carbide

3. Nico-based alloy

4. Fe-based alloy

5. Co-based alloy

Processing Techniques

1. Heat treatment

2. Quenching

3. Nitriding treatment

4. Bimetallic alloy welding for screw

5. Bimetallic alloy centrifugal casting for barrel

6. Hard-chrome electroplating

7. Linearity of screw:0.015mm

Technical parameters

Nitriding layer depth:0.5-0.8mm

Nitrided hardness:900-1000HV

Bimetallic layer depth:3 mm

Bimetallic hardness:57~69HRC

Hard-chrome plating hardness after nitriding:≥950HV

Chrome-plating layer depth:0.03-0.09mm

Surface roughness: Ra 0.4

Mini Single Screw Diameter from 16mm,18mm,20mm to 40mm

Common Single Screw 45mm,50mm,55mm,60mm,65mm,70mm,75mm, 80mm,85mm,90mm,95mm,100mm,110mm-220mm

Application:

Suit for HDPE, LDPE, LLDPE, PVC, PP, glass fiber, PPS, PPA, and other special plastic recycling.

Technological Process:

Blanking→Rough Machining→Quenching & Tempering →Semi Finishing Machining→Finish Machining→Nitriding or Bimetallic Treatment→Detecting→Finished Product →Debugging After The Sale

Advantages of screw barrel:

Advanced nitriding technology: we have our own nitriding oven equipment.

Duplex alloy spraying technology

High corrosion & abrasion resistance to prolong the lifetime of screw and barrel

Special alloy powders are sprayed and welded on the screw's ridge/flight, and use different alloy and welding methods for the screw of different functions.

For good plasticizing, it has many designs to meet customers' demands. Such as granular type, mutant type, wave type, barrier type, double screen type, shunt type, separation type, exhaust type, and so on.

The screw barrel is going to be upgraded to Stainless Steel

The barrel for 16mm extruder screw is designed for 35mm diameter band heater. Barrel for 20mm single screw will adopt 40mm diameter mica band heater.

Compression Ratios: 16mm extrusion screw is 2.5 and 20mm extrusion screw is 2.8

Planetary geared stepper motors are recommended for pellet extruders.

https://www.robotdigg.com/product/848/

https://www.robotdigg.com/product/2028/