Solder paste automatic feeding unit or manipulator

At present, in the process of solder paste printing in the mobile phone industry, the vast majority of customers are adding solder paste manually. But there are many disadvantages like wasting, low operation efficiency, easy to forget to add solder paste, and solder paste contains certain heavy metals harmful to human beings.

Only a small number of tin-filling manipulators on the market have special requirements for the specifications of tin bottles. Some customers require the provider to punch the bottom of the tin bottle, other customers require to replace the tin bottle packaging, which will increase extra cost.

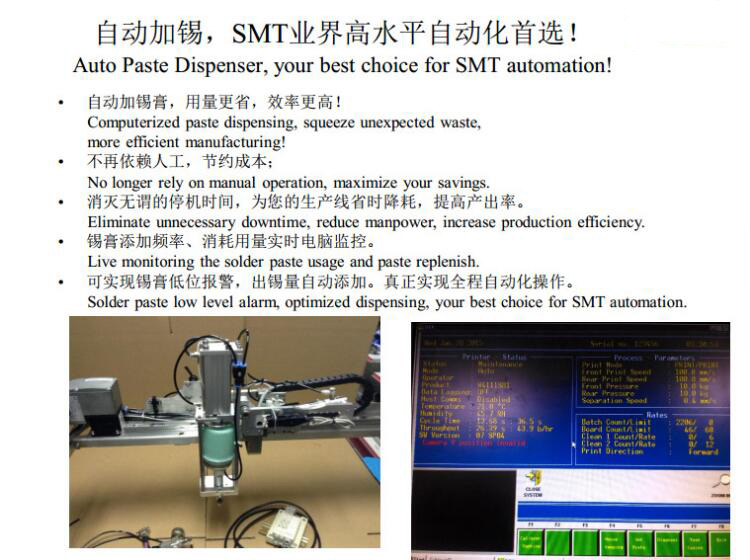

Automatic tin-filling manipulator is an automation equipment based on SMT industry. It has been widely used in the most related industry field, like intelligent terminal, consumer electronics and work server manufacturers. The feeding unit or manipulator can effectively reduce the production intensity of employees, reduce tin consumption, it's cost effective way to adding solder paste. Through modular design and precise software design, this equipment can realize linkage control with automatic printing machine. It can be widely used in solder paste printing, red glue and other different processes. It can automatically add tin, automatically monitor the height of the solder paste roll, alarm the solder paste cylinder less tin, and provide statistics function of frequency and dosage of solder paste on-line. It's a product with wide application prospects in SMT industry.

Automatic tin-filling manipulator for a series of products: for MPM series, for DEK series(including for Infinity or Horizon).

Advantages:

1. Compatibility, there is no special requirement for the packaging of tin bottles, can be compatible with more than 99% of the packaging bottles on the market, can be compatible with solder paste, red glue, flux and other fluids.

2. Intelligence, automatic feeding, monitoring solder paste adding frequency and consumption of real-time computing automatically, to achieve a low-level solder paste alarm, the amount of tin automatically added to avoid artificial forgetting to add solder paste caused by the omission, less adding problems, truly realize the whole process of automatic operation.

3. Economy, healthy and convenient, no longer rely on labor, saving on labor costs, eliminate ineffective downtime for your production line to save time and reduce consumption, use less solder paste but more efficient, improve productivity and SPI yield. It's enclosure solder paste feeding unit to avoid touch with toxic substances greatly and the health of operators were ensured. And it's easy to install and maintain