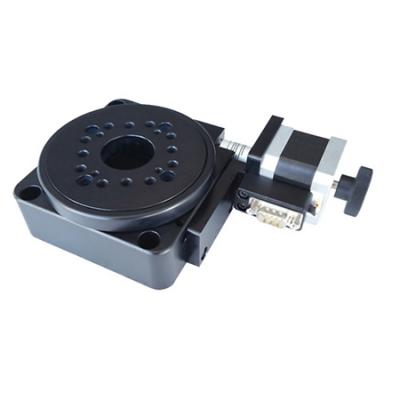

Stepper Motorized Rotary Table

New design the key index has up to the international level of the similar products by strict inspection. This series product is used for laser precision processing, three-dimensional scanning measurement system,s and so on.

Worm and worm wheel has adopted durable to friction material, high reliable accuracy of rotation.

High precision, ultra steel axes of importing, achieve high precision, high load stable motion. The outer circle has scale, interface, convenience for signal output.

A,

Standard stepper motor and DB9 interface, choose controller flexibility. We also can provide fully customized motion systems.

A regular stage set with a stepper motor and RS232 interface could connect with motion controller easily.

B,

*High precision Worm gear design for high accuracy, loading and long working time.

*Forward and reverse rotate are possible.

*The stage could use in vertical and assemble with other stages.

C,

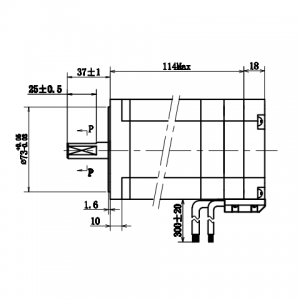

1. Prototype stepper motor 42 stepper motor (1.8°). Servo motor available for replacement on request.

2. Fine steel rotary shoe, high accuracy, massive loading capacity, and long using life.

3. Fine grinding worm drive with comfortable movement and backlash can almost be ignored.

4. Clearance elimination design.

5. The motor is connected with the worm via high quality elastic coupling, synchronized drive without noise.

6. Scaling on the outering of the platform, easy scale reading.

Electric Rotary Stage Structure specifications

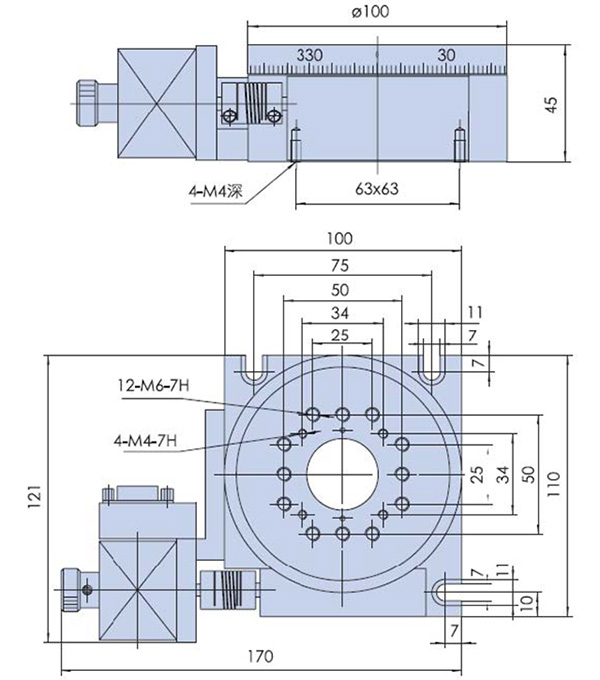

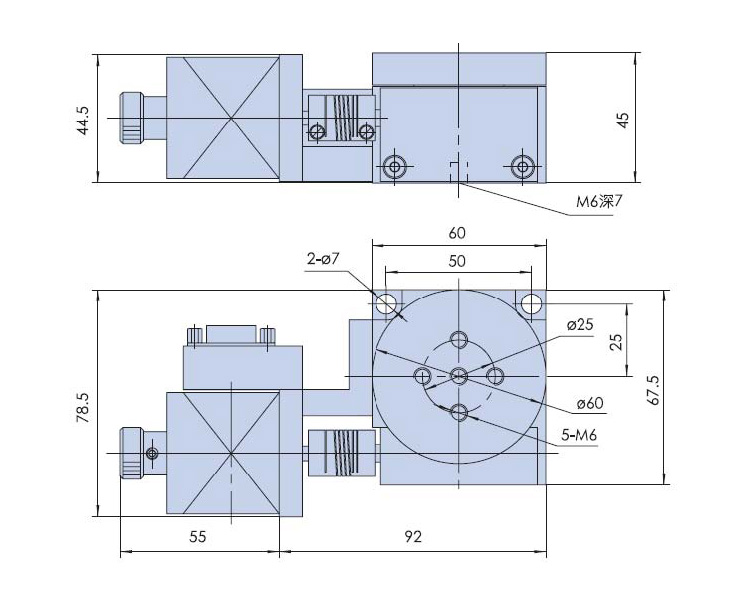

1 Part Number: PT-GD201

2 Rotation Range: 360° of Continuous Rotation

3 Diameter of Platform: Ø100mm

4 Drive Mechanism: Worm Gear

5 Worm Gear Ratio: 180 : 1 or 90:1(Choose one of the two)

6 Stepper Motor (1.8°): 2 phase bipolar, 1.8°step angle

7 Material and Finish: Aluminum Alloy, Black Anodized

8 Load Capacity: 45Kg

9 Weight: 1.7Kg

Accuracy Specifications

1 Design Resolution: 0.01°, Non-MS Driver

2 0.0005°=1.8", 20MS Driver

3 Rotational Velocity (Max): 25°/sec

4 Repeatability: 0.005°=18"

5 Absolute On-Axis Accuracy: 0.01°=36"

6 Run-Out of Top Plate: 15μm

7 Backlash: 0.005°=18"

8 Eccentricity: 5μm

9 Lost Motion: 0.005°=18"

10 Parallelization: 80μm

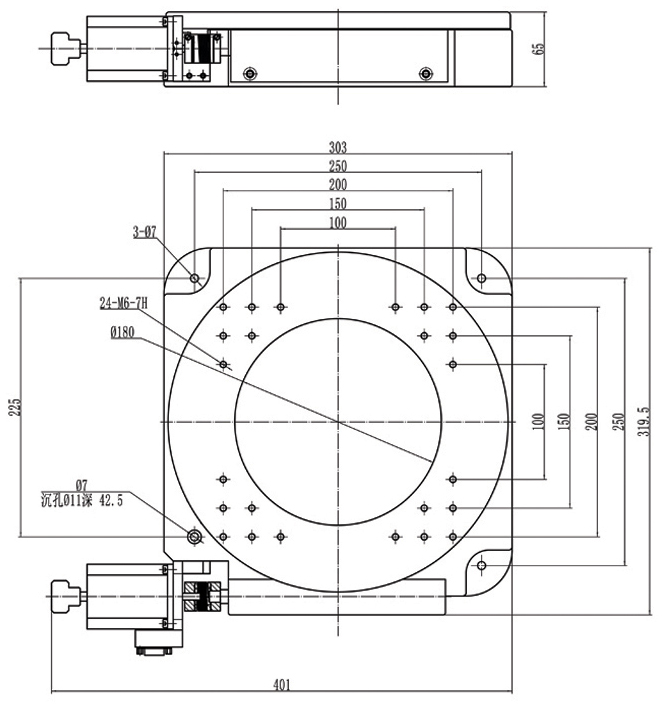

PT-GD203, PT-GD204

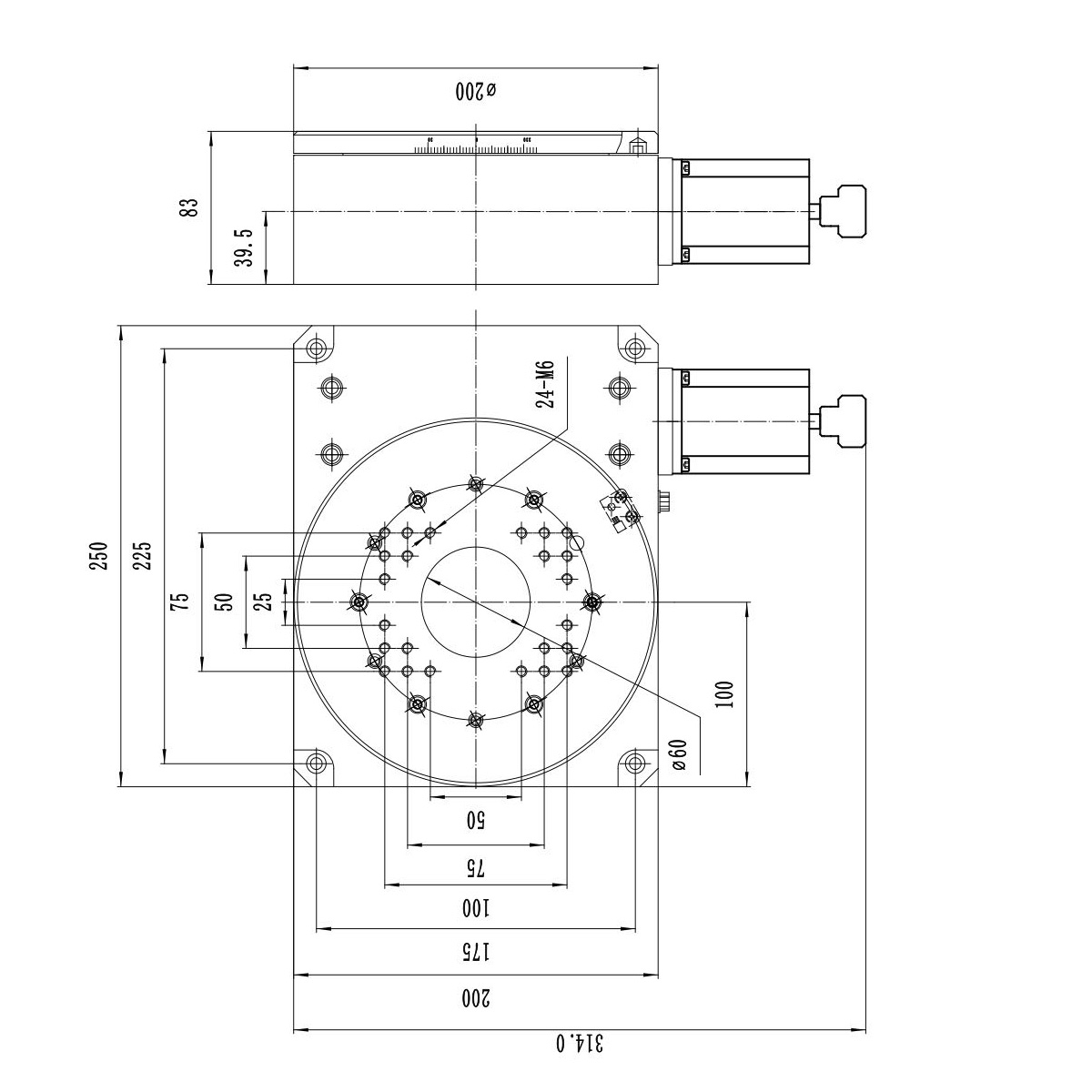

1 Item Number: PT-GD204

2 Rotation Range: 360° of Continuous Rotation

3 Diameter of Platform: Ø200mm

4 Drive Mechanism: Worm Gear

5 Worm Gear Ratio: 180 : 1or 45 : 1

6 Stepper Motor (1.8°): 57BYG - Stepping Motor with 2-Phases & 1.8° of Step Angle

7 Material – Finish: Aluminum Alloy - Black-Anodized

8 Load Capacity:100Kg

9 Weight: 12kg

Accuracy Specifications

1 Design Resolution: 0.01°=36", Non-MS Driver; 0.0005°=1.8", 20MS Driver

2 Rotational Velocity (Max): 25°/sec

3 Repeatability: 0.002°=7.2"

4 Absolute On-Axis Accuracy: 0.005°=18"

5 Run-Out of Top Plate: 10μm

6 Backlash: 0.002°=7.2"

7 Eccentricity: 20μm

8 Lost Motion: 0.005°=18″

9 Parallelization:50μm

PT-GD205 ratio 144 or 288