Motorized bicomponent screw pump

Stepper motor or servo motor (For servo motor and controller solutions please email us at sales@robotdigg.com for a quote and further.

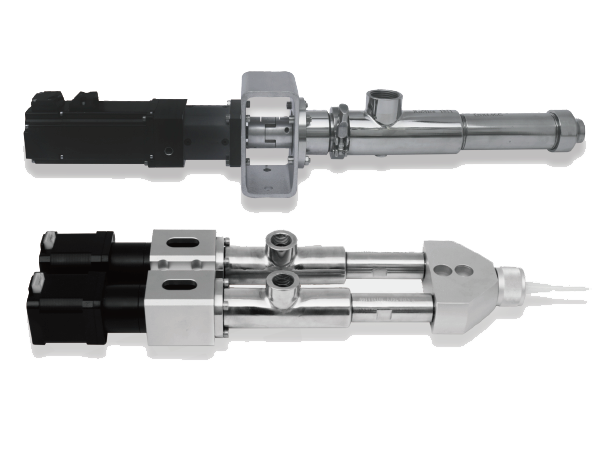

A two-component Mixture Unit is discharge equipment that combines two Dispensers, a static mixer, and a mixing block.

Static mixing tube

Features:

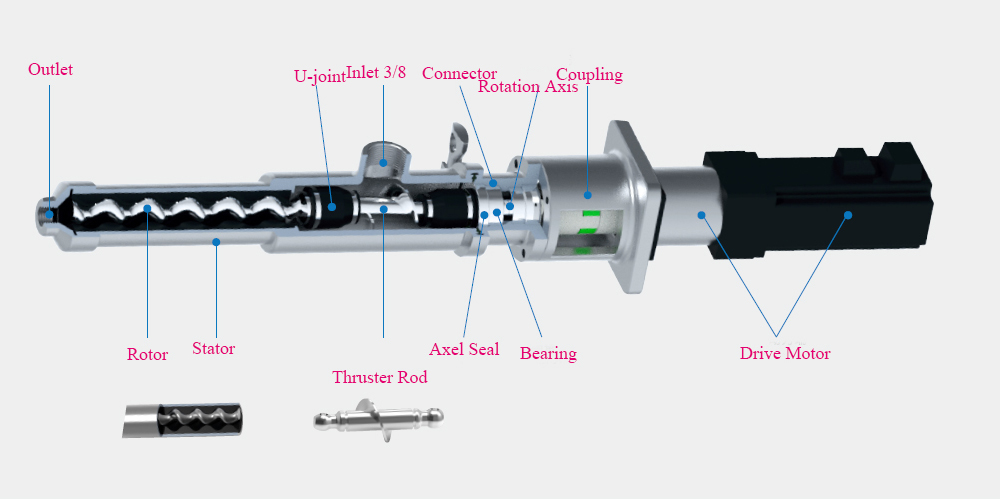

Easy to adjust the mixing ratio and discharge volume.

By controlling the rotation of the rotor, it is easy to control the mixing ratio and the discharge volume.

Stable discharge of high-viscosity fluids.

Capable of handling fluids of a wide range of viscosities.

No need for cumbersome post-cleaning processes

No dripping and no liquid accumulation keep works, containers, and accessories clean.

Application

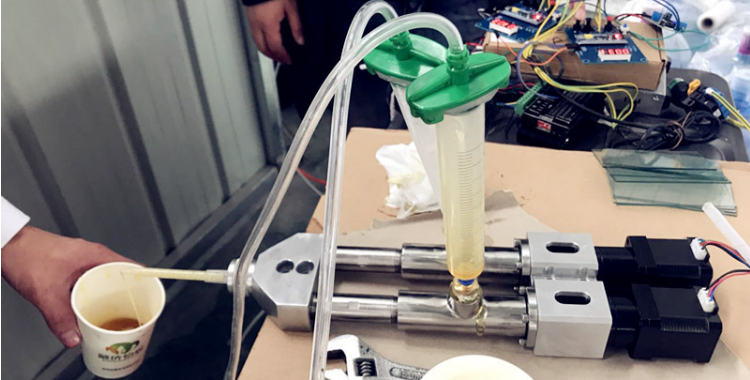

The motorized screw pump is used by manufacturers of the glue dispensing machine which can supply high viscosity glue, epoxy AB glue, polyurethane glue, silica gel, glass glue, etc. Also, it's suitable for the food industry, and can transport beverages, chocolate paste, syrup, butter, and other substances.

Applicable materials: epoxy resins, silicone resins

This dual screw pump can be used for A n B or AB bicomponent glue dispensing, Liquid Silicone Rubber (LSR) injection molding, or other mixture metering requests. The idea is quite similar to dual colors or multi-color 3D Printing and the screw pump function like the dual stepper extruder which is used to drive two colors of 3D filaments separately to finish the printing.

The inlet is 3/8, rotor and transmission 304, 316 or 316L Stainless Steel

Stator material natural rubber, styrene-butadiene rubber, nitrile rubber, EPDM rubber, fluorine rubber, hydrogenated nitrile rubber

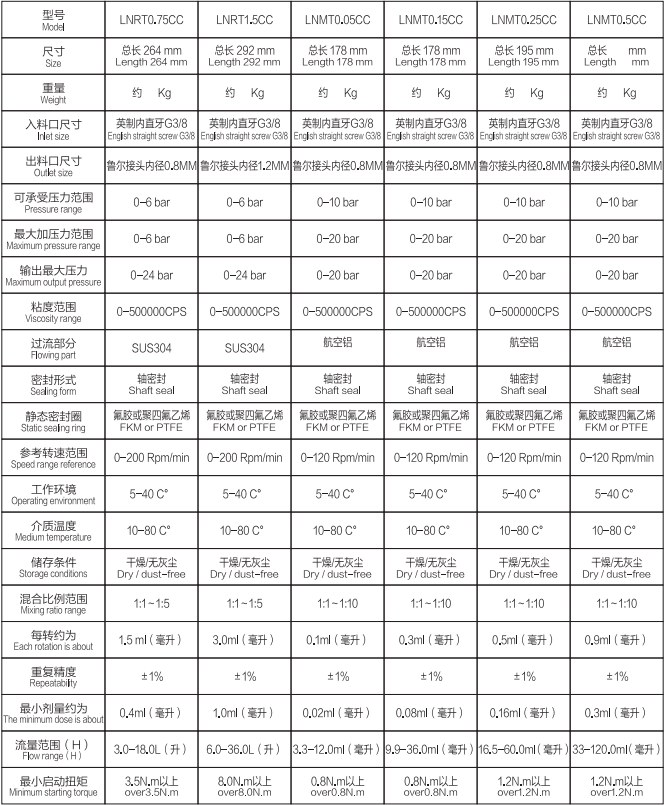

0.5CC and 0.15CC screw valves are available upon request.

For different ratios of A and B bicomponent dispensing, besides the motor ratio option, we also can provide you with a bicomponent valve in different combinations.