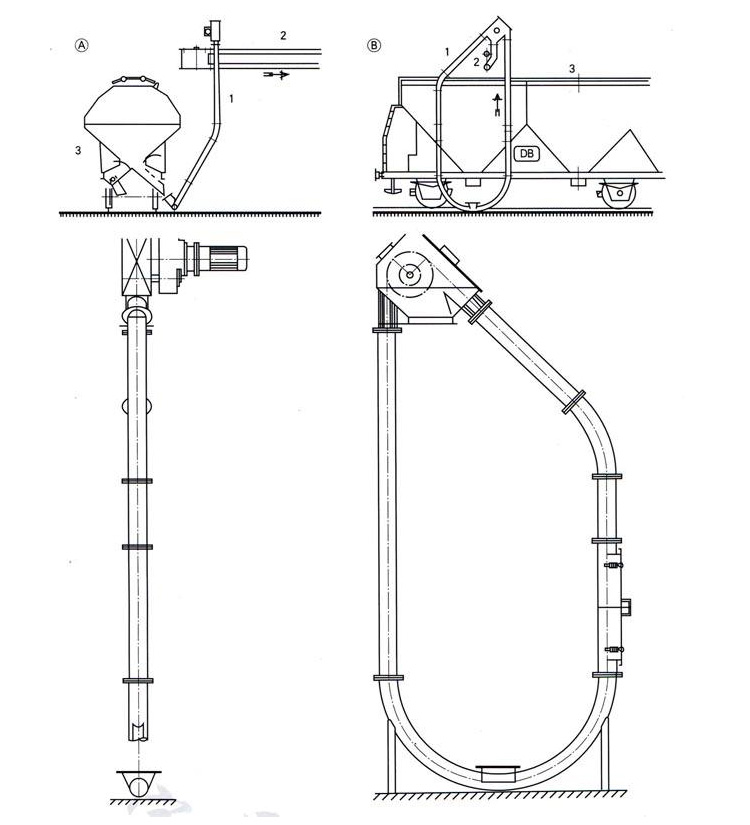

Tubular Drag Chain Conveyor

One of the most predominant perceived alternatives to the original tubular drag chain conveyor is the cable conveyor. And while it is a perceived alternative, chain-type tubular drag conveyors and cable conveyors cannot rightly be considered for the same applications.

Tubular Drag Chain Conveyors, sometimes called tubular drag conveyors, is a mechanical system that operates within the confines of a pipe.

Tubular Cable Conveyors, is a mechanical system that operates within the confines of a pipe.

1. Provides totally enclosed, dust-free, contamination-free handling, no need dust collector at the discharge.

2. Requires minimum horsepower and energy consumption.

3. Handles hot, cold, wet, dry, hygroscopic or temperature-sensitive materials.

4. Self-feeding with most flowable materials.

5. Gentle conveying action minimizes product attrition.

6. May discharge at multiple points in the circuit; no special airlocks are required.

7. Operates at a minimum noise level.

8. Easily assembled in the field.

9. Saving cross-section Space, can be installed where other conveyor types cannot.

10. Food grade, polished stainless steel chain for food and pharmaceutical applications in sanitary environments.

11. Wide range of sizes and materials of construction as required.

The feature is the stable property and saving the energy consumption in conveying system. It can contiguously convey powder, small particles and small lumps, and so on the bulk material, can convey in the level, the incline and the vertical. It is widely applied in the chemical industry, chemical fiber, agricultural chemicals ore, the food industry, the Building materials profession, etc.

Capacity = 300m3/h

Length: horizontal =80m Vertical =60m

Single machine power: =15KW

Pipe chain for PBAT production to send PTA and adipic acid (AA)