IBC Systems

IBC (Intermediate Bulk Container) system is a part of bulk material handling system that offer complete batch process flexibility. IBC systems are widely used in powder and bulk manufacturing as storage, transport and, with the increasing use of in-container applications, blending vessels.

Feature:

Controlled feed to process direct from the IBC with high accuracy.

Optimum process efficiency with “In bin” Formulation and Blending.

Dust containment before, during and after material transfer, with Operator Exposure Levels (O.E.Ls) designed to customers specifications.

Hygienic design, suitable for highly regulated industries such as Pharmaceutical & Food.

Specification:

Silo thickness: 6mm/10mm

Frame material: Carbon Steel, Stainless Steel

Volum:500L-2500L

Advantage:

Controlled Flow

No Segregation

No Degradation

No Dust

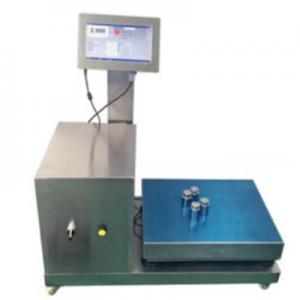

IBC Mobile Storage Bin

More than a Container

With technologies including the blending and discharging device, bulk valve and a deceleration device, common issues such as handling difficult to blend materials, poor flowing product and potent materials can all be met and addressed. The IBC System can be designed specifically for the pharmaceutical and healthcare industries. With product contact parts constructed from stainless steel, a range of finishes is available for both the internal and external surfaces. Modern construction techniques ensure accurate manufacturing tolerances are met with repeatable dimensional accuracy.