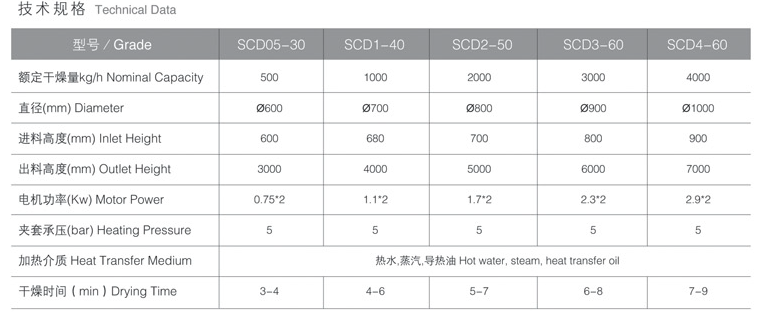

Vibration conveyor spiral elevator dryer

A dryer machine with two purposes can synchronously realize the drying and vertical conveying function.

Without mechanical force impact on the material during conveying, it's applied to requirements of the nondestructive conveying occasion.

With small land occupation, it's applied to the arrangement of various working places.

With low heating energy consumption, it adopts a heat-conducting medium to transfer heat through the jacket, its energy density is much higher than hot air, and it overcomes the shortcomings of the low capacity usage ratio of hot air in traditional fluidized bed drying.

With continuous movement of material in vibration, there is no material staying and heating time is stable and drying is uniform.

It can heat by hot water, steam, and conduction oil, with a wide heating temperature range, and precise and adjustable working temperature control.

Without external forced-air entry, it avoids impurity contamination in hot air completely.

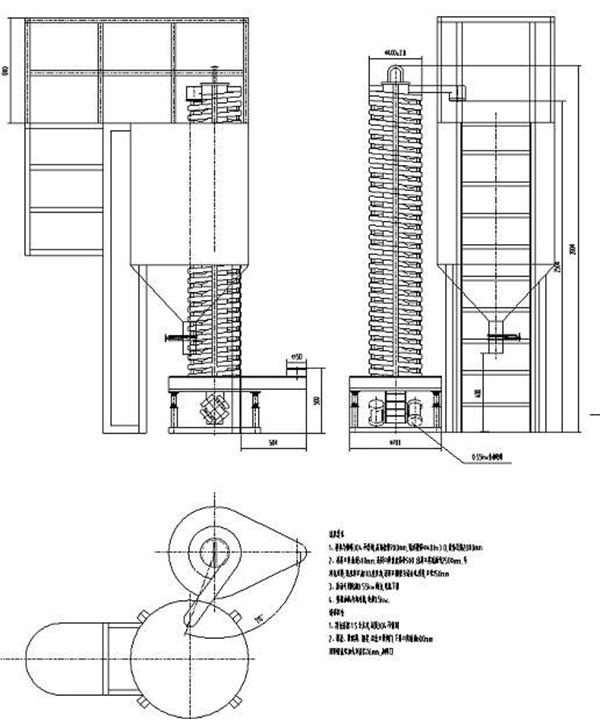

With strong generality, it can be designed for up-charging material and down-discharging material or down-charging material and up-discharging material with height customized according to customer requirements.

It can be designed to disassemble an insulation jacket structure to improve high thermal efficiency.

It can be designed enclosed air intake and exhaust structure to avoid environmental contamination of powdery materials.

It can be added nitrogen protection atmosphere to prevent material oxidative deterioration during high-temperature operation.

It can be adjusted conveying speed and conveying output by adjusting vibration frequency and exciting force to meet different dry-time requirements of various materials.

It can be added wear-resistant ceramic veneer layer to fi long-term conveying of high-hardness products.

Without a dead angle for overall equipment, it can be cleaned easily and adopt frequent switch between different materials.

Vibration Spiral Elevator Dryer Working Principle

It adds jacket heating function on the basis of the original vibration spiral elevator conveyor, and applicable to the working environment required for continuous dry operation. The material is heated to dry temperature adequately by vibration disk with a jacket during long-distance vibration conveying and vapor can diffuse through convection air.

Customer benefit

Its energy consumption is reduced obviously and comprehensive efficiency is improved obviously.

Dry technological conditions can be adjusted flexibly, and it has automated control, improving product quality and stable quality.

With continuous work and simple and convenient operation, the working force is reduced and the working environment is improved.