ICs pin Coplanarity Inspection Station

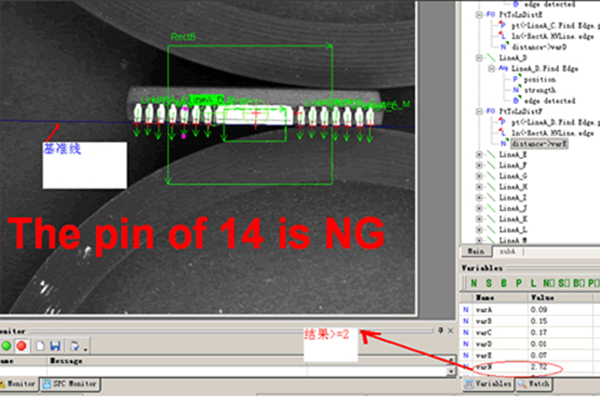

Automated 3D Inspection System that verifies pin height and true position using 3D technologies Machine Vision. A method for determining coplanarity of surface mount integrated circuit chips.

Coplanarity detection is sometimes called frontality detection and flatness detection.

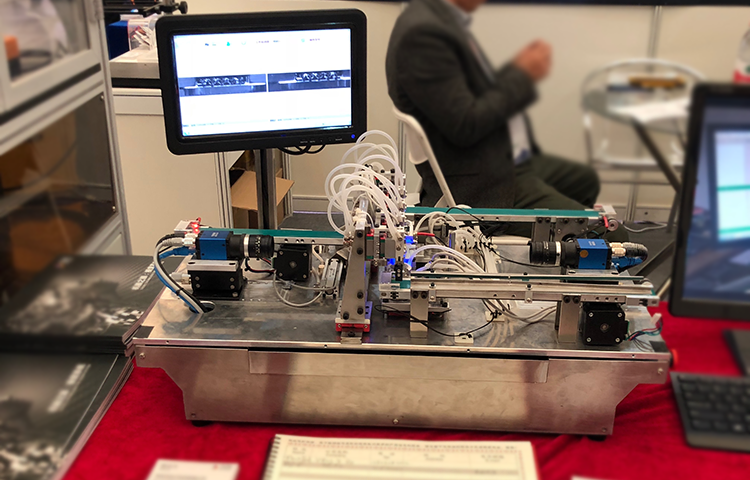

Coplanarity detection system is designed for inspection horizontal straight lines of pins of various electronic components such as IC chips, electronic connectors, inductors, and transformers

Indicators such as degree, coplanarity, gap, and stitch width.

1. The device is equipped with a sensor, which automatically recognizes and automatically alarms when it is found to be bad.

2. The measurement data is saved and can be viewed at any time.

Function: manual coplanar inspection station camera number: 2

Judgment accuracy: 99.99% (depending on the material) Vision size: 20*30MM

Camera resolution: 5 million figure smart industrial camera application range: inductance, IC and other pin components

Detection accuracy: ±0.01MM Dimensions: length 0.55* width 0.15* height 0.15 m

Detection speed: software 600 / min repeatability accuracy: ± 0.01MM

Why Coplanarity Matters?

The bending of a lead severely damages the package and may affect the reliability.

– The stress induced may result in microscopic cracks or chips in the package, and reduced adhesion, particularly where the lead enters. This reduces the ability of the package to resist ingress of moisture and may lead to failure through internal corrosion

• Coplanarity ensures all device pins or balls are within their manufactured tolerances. This is critical at board assembly

– Device pins are centered on pads prior to reflow

– Proper solder flow ensures solid pin-to-pad bonding

– Reduces the risk of solder fractures, cold solder joints and lifted pins

– Proper device seating and bonding are best suiting to withstand heat and vibration

• Coplanarity minimizes the risk of field failures, essential in mission critical applications such a automotive braking and missile guidance systems

Automatic Coplanarity Inspection

Modern electronic components such as BGA, CSP or Fine Pitch QFP, To ensure the conductive connection between the component and the substrate or circuit board before using we need to check if all contact points or conductors have approximately the same height. To check this we have to carry out a so-called coplanarity measurement. For this measurement, the height of each conductor or each contact point is precisely measured and the deviation of each conductor or point from a plane representing the subsequent position of the component on the substrate or circuit board is then measured. 3D inspection coplanarity check device or solution for Automatic Coplanarity Inspection is available from RobotDigg, please leave us message or write us email for more.