2-phase Digital Stepper Motor Driver

It is a fully digital stepper drive developed with advanced DSP control algorithm based on the latest motion control technology. Its motor auto-identification and parameter auto-configuration feature offers quick setup to optimal modes with different motors. Compared with other analog or TB6600H chips driver, it can drive a stepper motor at much lower noise, lower heating, and smoother movement.

Key Features:

* Anti-Resonance provides optimal torque and nulls mid-range instability

* Motor auto-identification and parameter auto-configuration when power on, offer optimal responses with different motors

* Multi-Stepping allows a low resolution step input to produce a higher microstep output, thus offers smoother motor movement

* 15 selectable microstep resolutions from 400 to 25600

* Soft-start with no “jump” when powered on

* Pulse input frequency up to 200 KHz, TTL compatible and optically isolated input

* Automatic idle-current reduction

* Suitable for 2-phase and 4-phase motors

* Support PUL/DIR mode

* Over-voltage and over-current protections

Electrical Specifications:

DM542 2-phase stepper motor driver

* Output Peak Current: 1.0~4.2A (3.0 RMS)

* Input Voltage: +20~50VDC (Typical 36VDC)

* Logic Signal Current: 7~16mA (Typical 10mA)

* Pulse Input Frequency: 0~200kHz

* Pulse Width: 2.5μS

* Isolation Resistance: 500MΩ

* Cooling: Natural Cooling or Forced cooling

* Environment: Avoid dust, oil fog and corrosive gases

* Operating Temperature: -10℃~45℃

* Vibration: 10-55Hz / 0.15mm

* Output Peak Current: 1.8~5.6A (4.0 RMS)

* Input Voltage: +20~50VDC (Typical 24-48VDC)

* Logic Signal Current: 7~16mA (Typical 10mA)

* Pulse Input Frequency: 0~200kHz

* Pulse Width: 2.5μS

* Isolation Resistance: 500MΩ

DM860H stepper driver

1. power supply voltage DC24-80V or AC18-50V

2. drive current 2.4-7.2A

3. subdivision intensive reading 2-200 subdivision options

4. optical isolation signal input

5. motor noise optimization function

6. can drive any two phase, four phase hybrid stepper motor of below 2.0A phase current

7.20KHz chopper frequency

Electrical characteristics

Input power: 24-80v, DC power supply, capacity: not less than 200VA. typical value: DC36V

Input current: 2.4A-7.2A, 8 adjustable, resolution 0.5A

Drive mode: double machine constant current PWM drive input

Insulation resistance: >500M Omega at normal temperature

Insulation strength: 500V/ minutes at normal temperature

Weight: about 400 grams

Environmental requirements

Cooling mode: natural cooling

Use occasions: avoid dust, oil mist and corrosive gases.

Ambient temperature: 0 C -+50 C

Environmental humidity: <80%RH, no condensation, no frost

Vibration: maximum no more than 5.7m/s2

Driver input signal interface function

Signal interface

Signal pretext

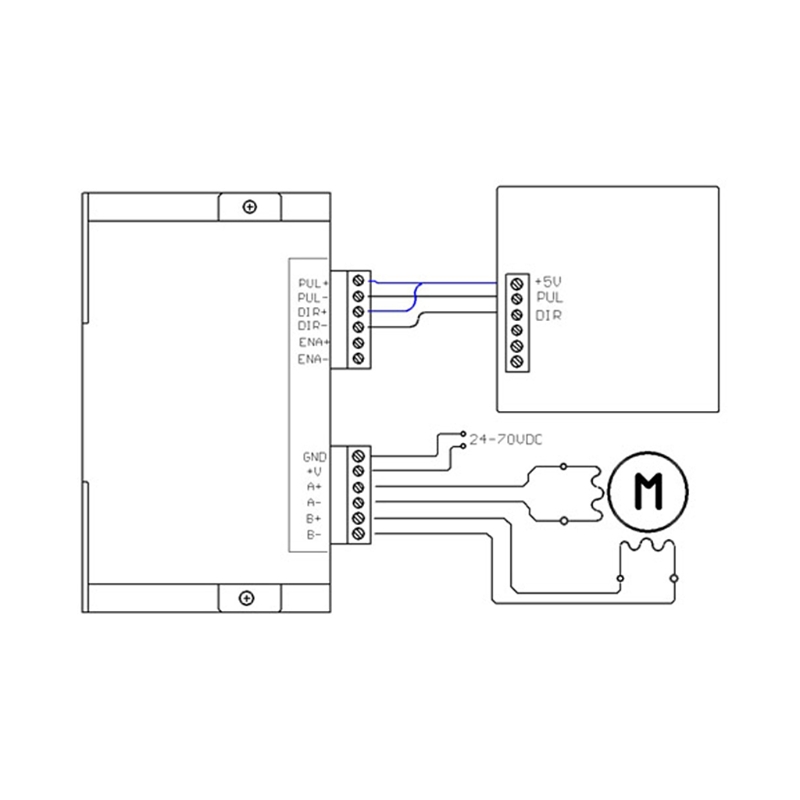

PLS+ and PLS- control the positive and negative end of the pulse signal. DIR+ and DIR- are the positive and negative ends of the direction signal. 24V needs 2K resistors

A+ and A- connect the positive and negative ends of stepper motor A phase winding, B+ and B- connect the positive and negative ends of stepper motor's B phase winding. When the A.B two phase winding is switched, the direction of the motor can be reversed

Motor Interface

Using the DC power supply, the working voltage range is suggested to be 20-50VDC, the power supply’s power is more than 100W. According to the actual use, the input is suitable for less than DC 40V

Indicator light

The driver has two indicators:red and green. The green light is the power indicator. When the drive is in charge, the green light is always on. The red light is the fault indicator. When overvoltage and overcurrent occurs, the red light is on. After the fault is cleared, the red light goes out. When the driver fails, recharging and reusing is needed to remove the fault.