BGA Wave Temperature Control BGA Rework Station

Features

1, powerful and perfect function selection, memory eight temperature curve, the user can choose according to the welding requirements of arbitrary heating curve;

2, intelligent curve heating, according to your preset temperature curve automatically complete the demolition process, so that the whole process of more desoldering desorption;

3, three-dimensional adjustment lamp body, retractable carriage system, suitable for any angle components of the demolition of welding, infrared light body with a laser positioning, so that more convenient positioning more accurate;

4, PID intelligent temperature control technology, temperature control more accurate, more perfect curve, can effectively avoid the rapid warming or continuous heating caused by chip or circuit board damage;

5, ultra-high power preheating melt system, and the use of independent research and development of infrared heating devices, penetrating power, the device heat evenly, more accurate temperature control. PGA, SMD, CSP, LGA, QFP, PLCC and BGA ball, all kinds of plug and pin socket (such as CPU socket and GAP plug), fully able to meet the computer, notebook, BGA desoldering / rework requirements, the computer north and south bridge demolition welding is particularly appropriate;

6, Perfect LCD display;

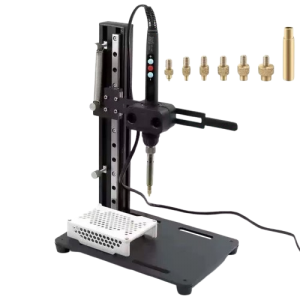

7, Fortitude appearance, lightweight size, from beginning to end reflects the technology-based. Table-style placement mode

Technical Parameters

Machine power 1500W

Rated voltage and frequency AC 110-230 V 60 / 50Hz

Infrared lamp body power 300 W

Infrared preheat chassis power 1200 W

Working table size 320 X 330 mm

Infrared lamp body effective heating area 60 X 60 mm

Preheat Chassis Preheat Dimensions 245 X 260 mm

Preheat chassis temperature adjustable 0 ℃ -350 ℃

Dimension 316mm X 410mm X 290mm

Net weight 9.3 kg

Packing List

Soldering station main body

Infrared lamp body

Gantry 2

Power cord

User manual (CD) 1

Curve Details

Curve 1, suitable for welding less lead content of the solder; such as: 85Sn / 15Pb 70Sn / 30Pb, etc .;

Curve 2, suitable for the removal of lead less than the amount of solder; such as: 85Sn / 15Pb 70Sn / 30Pb, etc .;

Curve 3, suitable for welding lead content of more solder; such as: 63Sn / 37Pb 60Sn / 40Pb, etc .;

Curve 4, suitable for the removal of lead content of more solder; such as: 63Sn / 37Pb 60Sn / 40Pb, etc .;

Curve 5, suitable for welding high melting point lead-free solder; such as: Sn / Ag3.5; Sn / Cu.75 Sn / Ag4.0 / Cu.5 Sn95.5 / Ag3.8 / Cu0.7 and so on;

Curve 6, suitable for demolition of high melting point lead-free solder; such as: Sn / Ag3.5; Sn / Cu.75 Sn / Ag4.0 / Cu.5 Sn95.5 / Ag3.8 / Cu0.7 and so on;

Curve 7, suitable for welding lead-free solder in the melting point; such as: Sn / Ag2.5 / Cu.8 / Sb.5; Sn / Bi3.0 / Ag3.0 and so on;

Curve 8, suitable for demolition of the melting point of lead-free solder; such as: Sn / Ag2.5 / Cu.8 / Sb.5; Sn / Bi3.0 / Ag3.0;