Desktop pellet filament extruder

https://www.researchgate.net/publication/343401328_The_3D-Printed_Bilayer's_Bioactive-Biomaterials_Scaffold_for_Full-Thickness_Articular_Cartilage_Defects_TreatmentMore than 5pcs can make OEM.

Manual of Extruder Line II

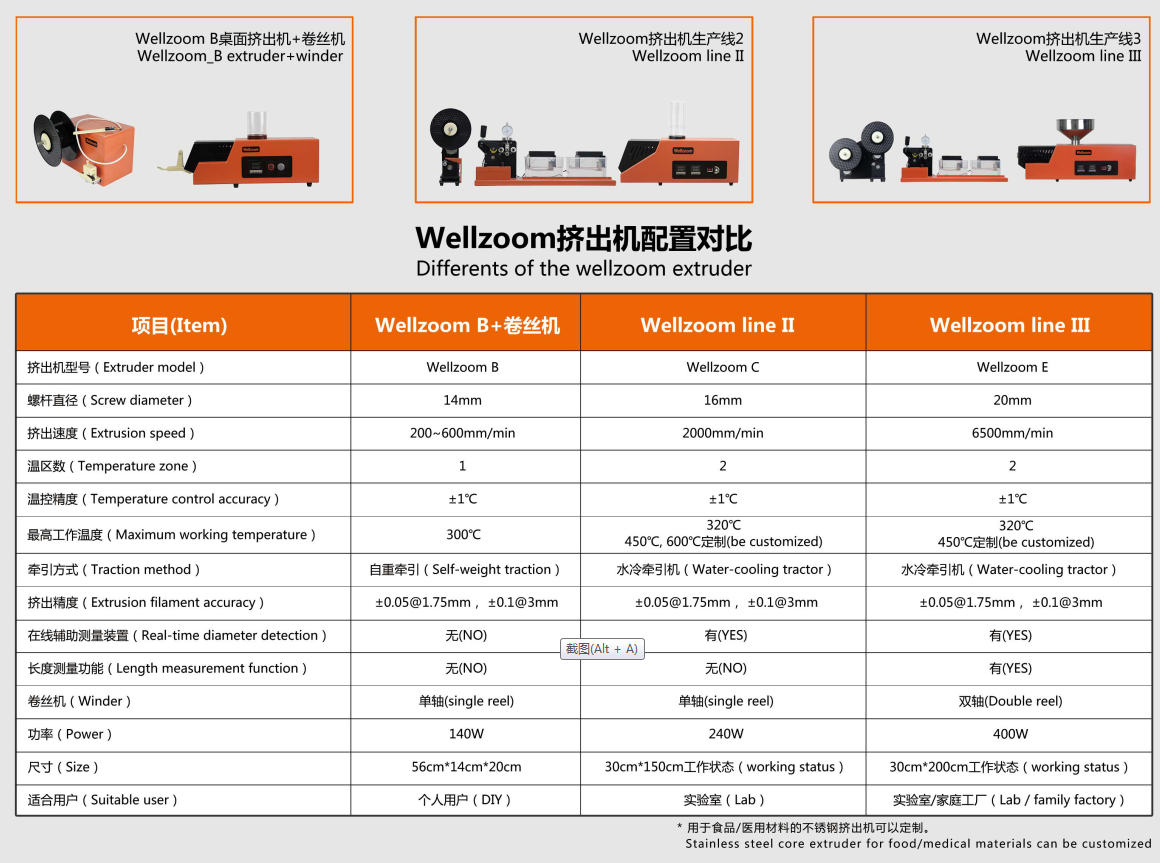

Main Difference between Model A, B and C.

1, Extrude Speed:

A,B:300-650mm/min;

C:1800-2500mm/min

2, Adapt Materials,

A,B:Nylon,PLA ,ABS, PVA,PVA,PP,PS and wood-plastic etc.

C:Nylon,PLA ,ABS, PVA,PVA,PP,PS and wood-plastic etc.(Normal Temperature type),PEEK, PEI etc (High temperature more)

3, Working temperature

A: 220-300℃

B: Below 300℃

C: Below 320℃(max 600℃ need customizing)

4, Power

A,B:150W

C:240W

5, Biggest size of the applied particle

A,B:3-4mm

C:6-7mm

PARAMETERS:

1. Extrude Speed: 300mm/min~650mm/min

2. Diameter: 1.75mm and 3.00mm( 2 nozzles)

3. Adapt material: PLA ,ABS, PVA and wood-plastic etc.

4. Working temperature: below 300℃

5. Temperature control accuracy: +/- 1 ℃

6. Power: 150W

7. Power Supply:220V AC,50 or 60Hz(110VAC,50Hz to be customized)

8. Size: 502x135x252(mm)

FEATURES:

1. Simple and beautiful appearance

2. Multiple protection to ensure that equipment work with high reliability

3. Easy to operate

4. Special screw, high-efficiency extrusion

5. Easy to clean the material cavity and change the nozzle.

6. Able to meet most of the thermoplastic materials.

7. Able to color. It can meet your needs about the color and material of filament.

8. Air-cooling + self-weight traction, making it more convenient and efficient.

Wellzoom Desktop pellet filament extruder(B)

A type improved, low power consumption, with speed control function

PARAMETERS:

SIZE:502x135x252(mm)

EXTRUSION SPEED:300~650mm/min

TEMPERATURE RANGE:below 300℃

POWER SUPPLY:220V 50Hz(Customizable 110V 50Hz)

POWER:150W

Desktop 3D Printing Filament Extrusion Line

Desktop extruder line is a tiny 3D supplies extrusion production line, it has a complete process that includes turning pellets into filaments, water-cooling and winding.

The desktop extruder is specifically designed for non-professional operators, especially for laboratories. The design is based on a simple concept. A simple operation panel can reduce the risk of misoperation; a well-designed structure can effectively avoid scalding operators.

If you want to produce new composite material for experiments or produce in small quantities, a Desktop extruder production line would be an ideal choice.

Desktop extruder lines include Wellzoom C extruder, water-cooling tractor, and auto winder.

Parameters:

Extrude Rate: 1800mm–2500mm/min

Adapt material:Nylon,PLA ,ABS, PVA,PVA,PP,PS and wood-plastic etc.

Working temperature: below 320℃(max 450℃ need customizing)

Temperature zones: Two temperature zones (Independent Control)

Accuracy of PID: +/- 1℃

Accuracy of filament: 1.75mm,+/-0.05; 3mm,+/-0.1

Power:240W

Power requirement: 220V,50Hz or 110V,50Hz

Diameter: 1.75mm and 3.00mm( 2 nozzles)

Desktop pellet filament extruder(C)

1. Simple appearance, easy to operate,

2. Easy to clean the material cavity and change the nozzle.

3. Special screw, high-efficiency extrusion

4. Able to meet most of the thermoplastic materials.

5. Able to modulate color. It can meet your needs about the color and material of filament.

6. Large-capacity hopper is transparent, you can easily monitor and add material

7. Dual-zone & independent temperature control can meet the requirement better for the composite material. Preheat zone is for melting materials. The extrusion zone is for controlling extrusion temperature.

Water-cooling tractor

1. The use of a stepping motor, with a stable traction speed

2. Stepless speed

3. The water-cooling or forced air cooling (forced air cooling module needs to be purchased separately) can be selected.

Auto winder

1. Own control technique, use photoelectric switches to detect position.

2. Automatically match the extrusion speed of the extruder.

3. The arranging mechanism can arrange the filament in order.

Pellet Extrusion Line 1st Generation

Extruder Line II

Water-cooling tractor applied.

After more than two years, on the basis of the original product, we have made a deep improvement. The second-generation products - Desktop Extruder Line II were invented. They have the following advantages:

1.On-line measurement function. It provides a low-cost detection method to control the diameter of the filament.

2.Redesigned auto winder. It’s more simple and reliable.

3.A variety of cooling combinations(can be chosen). Such as double sink cooling, forced air cooling & water cooling combination, air cooling, low-temperature water cooling (15℃ below room temperature). They can adapt to different kinds of materials.

Water-cooling tractor

1. Stepping motor is used to ensure stable traction speed.

2. Stepless speed control.

3. On-line measurement function.

4. A variety of cooling combinations can be chosen. We can provide the best solution.

Extruder Line II+ 450℃

Maximum extrusion speed: 4000mm / min(1.75mm, ABS)

Suitable materials: ABS, PLA, Nylon, wood plastic, PVA, PS, PEEK and so on

Solution of small batch production of PEEK 3D printing filament

Operating temperature: below 450℃

Temperature zone: 2 temperature zones (independent control)

Temperature control accuracy: ± 1℃

Accuracy of filament: 1.75mm, + / – 0.05; 3mm, + / – 0.1

Power requirement: 220V, 50Hz (110V, 50Hz need customizing)

Power: 220W-440W

Nozzle: 2 nozzles for 1.75mm and 3mm 3D Printing Filament(1.8mm, 3.2mm)

20mm extrude screw Extruder Line III

II Tractor n Winder

III Tractor n Winder