Reflow or Wave Soldering Ventilation

Soldering Ventilation

Either reflow soldering or wave soldering for batch production we need to consider of the soldering ventilation indeed.

Questions:

"(a) The fume from the reflow or wave soldering machine is leaking to the surrounding although it is enclosed and attached to the local exhaust ventilation system with a capacity of 5000 CFM.

(b) Current local exhaust ventilation system or the portable exhaust fans are found not efficient in extracting the fume during soldering at single workstation."

Answers:

"The most IMPORTANT thing about fume capture is to have the fume hood as CLOSE AS POSSIBLE to the source.

A minor point, which determines somewhat the fan static pressure, is the sizing of the ducting ... in your case I'd opt for max. max. 3,000 fpm."

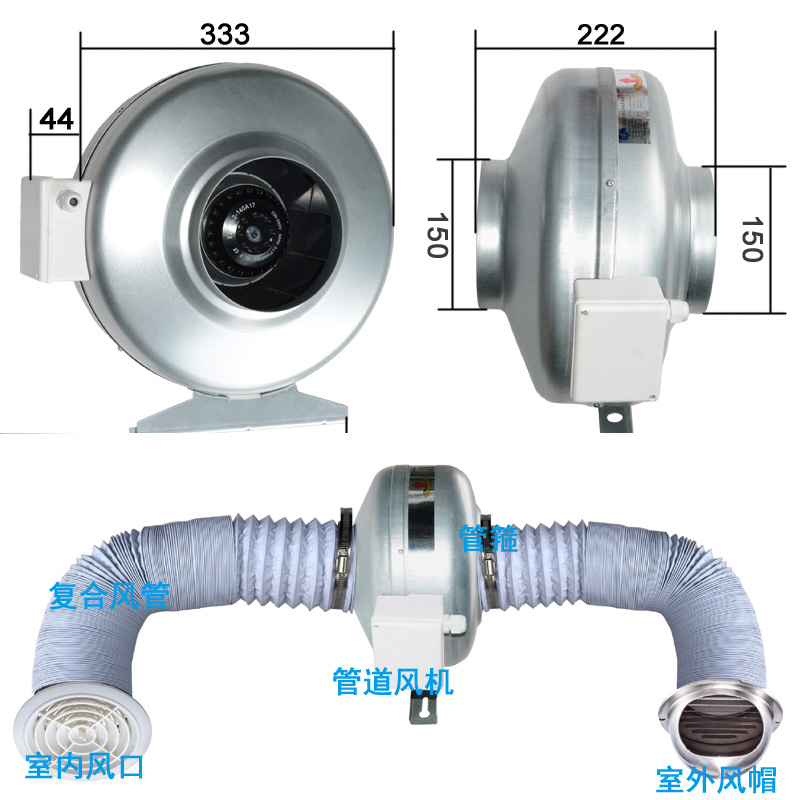

Ventilation Pipe

The reflow or wave soldering vent pipe is a high-temperature resistant pipe used in the reflow or wave soldering, mainly for the function of exhausting and extraction fume. The reflow or wave soldering pipe can be made of PVC plastic pipe or Tin Plate pipe. The connecting pipe adopts mostly the soft air duct pipe with steel wire reinforced for extraction of soldering fume, for air conditioning and ventilation equipment, reflow soldering, soldering station fume hood, assembly line exhausting, etc.

The most common ones currently used in reflow or wave soldering are aluminum foil duct and the other aluminum foil fiberglass composite duct. Pure aluminum foil is thin, and it is easy to break with a pointed object, but the price is relatively cheap. The aluminum foil fiberglass composite duct is made of a glass fiber cloth in the middle of the double-layer aluminum foil, which solves the problem that the pure aluminum foil duct is easy to be broken. PVC telescopic ducts are also relatively low cost and low quality, using a PVC with a coated cloth, which is a better substitute for PVC telescopic ducts.