TYPES OF PULLEY MOUNTING

Timing Pulley Classification by Mounting

Beginning with the most inexpensive options, good for fitting into tight budget scenarios where the load is not a big constraint, set screws provide security for only the lowest loads. These use friction of the set screw against a set screw flat on the shaft for their holding power.

With the addition of a keyway, they can provide a mounting solution for low and medium loads, while still maintaining low cost. Often when installing, the timing (or orientation) of the pulley cannot be adjusted freely since the set screw fits to a set screw flat, and a keyway and key fit in only one orientation.

Offering some clamping force, with the ability to make more fine-tuned adjustments to the timing of the pulley, a split-hub also offers a relatively low cost solution for medium loads as well.

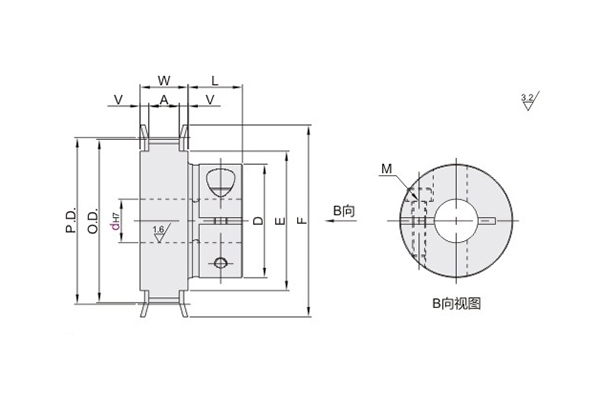

An older technology, used primarily on HTD high load applications, Quick Disconnect (or QD) bushings tighten on a shaft and allow the user to mount from either side of the sprocket.

Finally, for the highest load applications, the Taper Lock, also known as the Keyless Bushing, is very flexible for design, giving users options to mix both Imperial and Metric bore sizes. This unit, while very popular, does have some drawbacks, namely that it can only mount from 1 side, thus limiting its effective in-application utility.