9 best Resin (DLP/SLA) 3D Printers of 2017

Stereolithography (SLA) may trail behind FDM 3D Printers with regards to shopper deals, yet as far as quality you'll see that a SLA 3D printer is generally the approach.

Both 3D printing advances are still in their early stages the extent that the purchaser showcase goes, having entered the home and independent company advertises just moderately as of late. 3D printing has been around for quite a long time, thus have their comparing licenses. As the innovation and materials progress — and licenses terminate — the business hole amongst SLA and FDM printing should rapidly restricted.

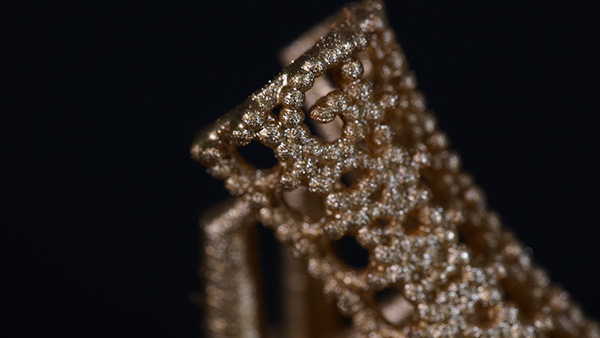

Obviously, quality is the thing that we for the most part make progress toward with regards to our 3D printing tries. While the dominant part of the present FDM printers will create a better than average model, contrast a FDM print with one delivered by any SLA 3D printer and you'll rapidly observe that SLA leads the pack with regards to the general nature of wrap up.

There's a justifiable reason motivation behind why FDM printers are the mainstream decision; they're quick, generally perfect, and shabby. By correlation, a SLA 3D printer is moderately moderate, untidy, and even the least expensive models are as yet costly.

Taking a gander at the most recent age of desktop SLA 3D printers, both the cost and multifaceted nature is rapidly falling. There are currently many models accessible for under $5000.

With numerous SLA 3D printer models being reasonable, the individuals who require top notch prints ought to consider dove in. Here we investigate a portion of the best esteem tar 3D printers available today.

In our rundown, we considered just SLA and DLP 3D printers that cost under $7,000, so this forgets the greater part of the modern 3D printers by organizations, for example, EnvisionTEC, DWS, Prodways and others. Among the bigger 3D printer makers, just 3D Systems makes the rundown with its ProJet 1200.

The point here is to offer you purchaser printers that waver in the middle of moderateness and quality.

The shared trait of DLP and SLA 3D printers is that they both utilize gum based photopolymers as consumables. These are fluid materials that respond by cementing when struck by a powerful laser or light source.

There are two approaches to "initiate" the photopolymerization response; one is by utilizing a laser to "draw" the question's layers. This is called unadulterated stereolithography (SLA).

Another is by anticipating the whole cut of the protest utilizing a computerized light projector. This procedure is called advanced light handling (DLP).