Outline of Stepper Motor

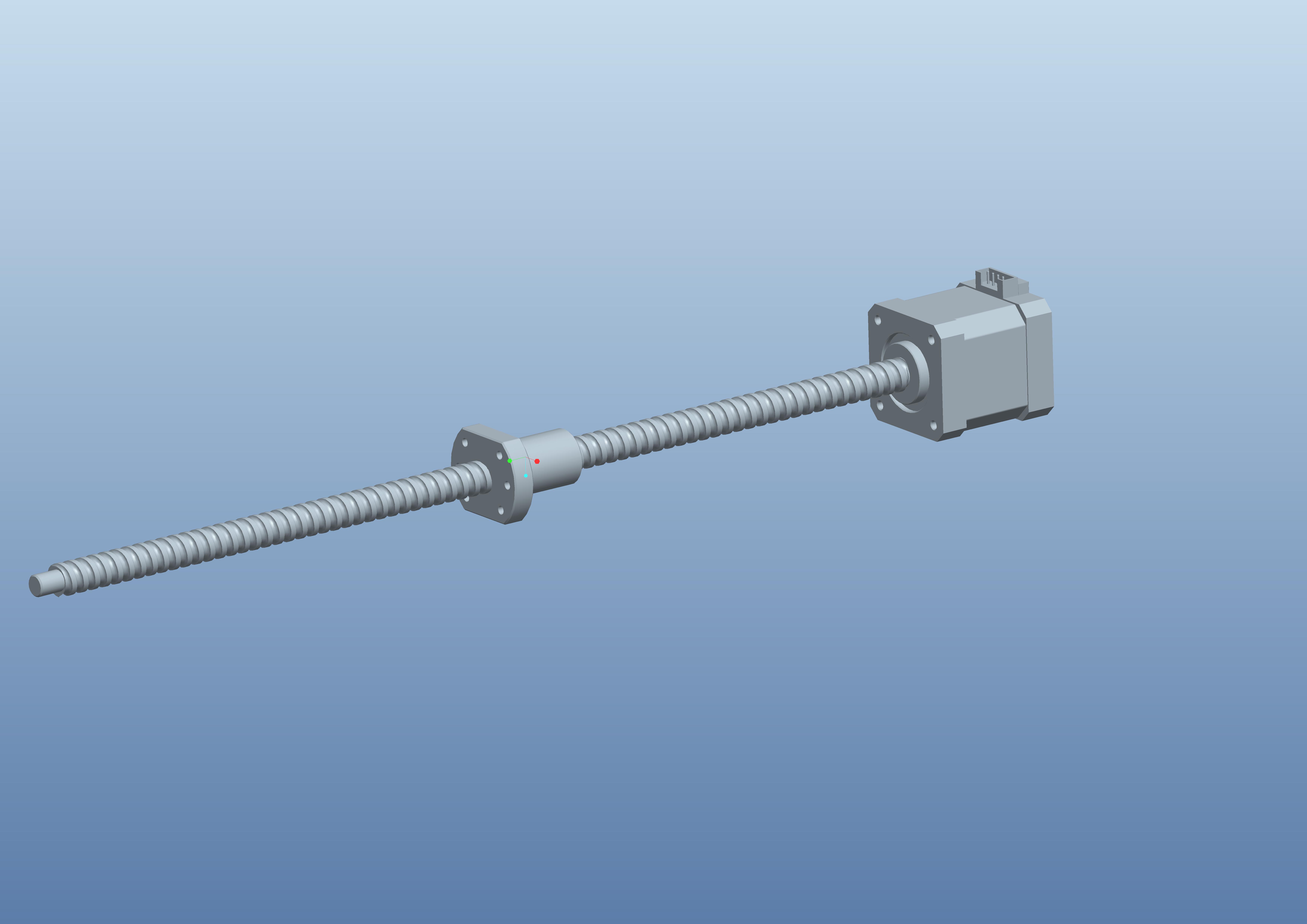

Hi, this is Tiger Huang from RobotDigg, today’s topic is “Outline of Stepper Motor”, here you can see is a Nema17 4 lead wire bipolar 1.8 degree single stack linear stepper motor.

Let’s dismiss the linear stepper motor to find out what’s inside and the factors of a stepper motor.

Firstly it’s stepper motor, not servo motor or normal dc motor.

There is only one piece magnetic steel which should be size 1.5mm thickness and the Torque is out of this piece of magnetic steel, it’s a single stack stepper motor. There are double stack stepper motor, here is the Nema17 48mm and 60mm steppers that both motors have double stack which means there are two pieces of magnetic steel inside.

You can see there is a similar piece of magnetic steel in the middle of the double stack But which is Not. It’s a magnetic isolation piece normally made of aluminum.

There are cheaper stepper motors from China, you will find a thinner magnetic steel piece something like 1.2mm or even 1mm thickness. And even worse that the magnetic isolation piece was replaced by kind of oily paper card.

Some opinions on popular arguments,

The first one is "Does it matter to open the stepper motor? And the motor won’t work or loose torque?"

RobotDigg’s answer is that it’s really matter in long run and especially in complex electromagnetic environment.

No more explains here. To protect copy of a motor, ever before the stepper motor loose magnet after breaking immediately. And in this case, the faker can Not measure out the specifications.

A history about stepper motor in China.

Stepper motor’s origin in China is Baoma Motor Group, a story heard and popular in group of people who are either in manufacturing or selling of stepper motors in China. Shortly Baoma in all following speakings. It seems the story can Not be found in internet, not sure about the reason. Baoma imported two production lines separately from Japan and Germany in eighty 20th century.

Baoma was a country own company, at that time, the business was very good, wholesalers, resellers and end users needs to prepay 2 month or even longer for motors.

MOONS' was founded in 1994 and in 2000, Fulling Motor was founded.

Sorry far away from stepper motor, let’s digg out further in short after. Come back to the main topic, stepper motor is wide range power supply and need stepper driver to get it work. Wide range of power supply means that it can work in usual 12-48VDC. The rated voltage is the lowest voltage needed to get the motor energized. Why talking about this, that is because end users are Not all clear about this and in thoughts that the stepper motor can only work at it’s rated current or asking for a 12V stepper motor.

The stepper motor applications are as many as rotary motion do. Not exactly, linear stepper motor is available for linear motion applications.

Stepper motor size from Nema8 to Nema42 were and are manufactured in numerous in China. Ultra flat, hollow shaft stepper motors are designed and manufactured for special applications. E.g, ultra flat stepper motor is used for electric feeder and hollow shaft stepper motor is adopted as SMC motor for SMT industry.

Geared stepper motor, gear box is getting rare while planetary gear head raise in market for its precision and cost performance. Worm gear stepper motor is used for cross directional transmission. And harmonic gear stepper motor is used for high end robotics and machines.

The gear head is Not only enhance the output torque and lower the speed but also micro-stepping the stepper motor by mechanical point the Ratio. So if there is a question that a 0.9 degree geared stepper motor is better option than the 1.8 degree one, the answer is Not exactly.

Beside the above, RobotDigg provides kinds of stepper motor auxiliary, Damper, Mounting Plate, Lead Wires, etc. Combination items stepper motor with brake, integrated stepper motor with controller or driver. Linear stepper motor will be my next topic, thanks.

Speaker

Tiger Huang

Founder of RobotDigg